About Bradley Pulverizer

Bradley Pulverizer was founded in 1886 in Boston, Massachusetts. Our first single roll pulverizers were used in fertilizer plants grinding phosphate rock and in cement plants grinding raw material and clinker. To meet the growing demand of the fertilizer and cement industries, Bradley Pulverizer quickly expanded its pulverizing mill offerings.

In 1914, Bradley Pulverizer established their own manufacturing facilities in Allentown, Pennsylvania, which was then the center of the cement manufacturing industry of the United States. At about the same time, Bradley Pulverizer also established sales and engineering offices in Europe.

Today, Bradley Pulverizer remains headquartered at its Allentown location with a facility in the United Kingdom. Our continued innovation and dedication to our customers continues to be a guiding force for Bradley Pulverizer for over 130 years.

Worldwide Presence

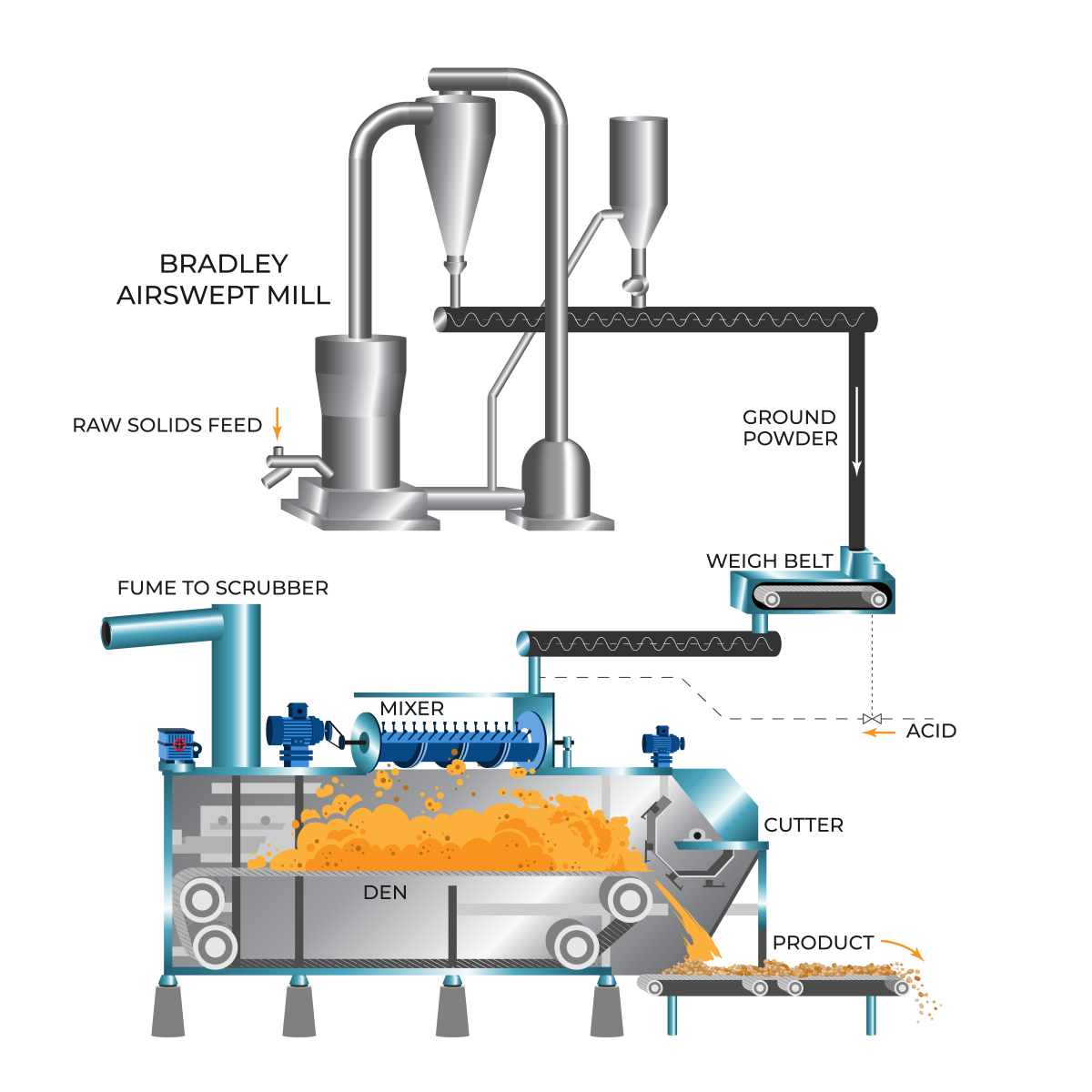

With a tradition and commitment that began with the renowned single roll Griffin Mill, today Bradley produces reliable, low maintenance, energy-efficient pulverizing and classification systems available throughout the world. Our mills are particularly well suited for plant operations requiring finely ground mineral products in industries such as cement, phosphate fertilizer, and steel.

Bradley systems operate in over 40 countries in many industries, including cement, steel, fertilizer (such as phosphates), petroleum, (barite and bentonite), mineral fillers, clay, coal, utility (limestone grinding for SO2 removal), pulp and paper, chemical, pigments, building materials, and much more.

Our Products

As specialists in the design, manufacture, and deployment of pulverizing systems for fine and semi-fine grinding and classifying, we can supply the optimum system from our complete line of pulverizers and classifiers. Our systems are employed in various applications throughout the world and are best suited for use with hard, friable and/or abrasive materials.

Bradley pendulum roller mill and classifier systems range in output from <1 to 150 tons per hour – with adjustable and uniform particle sizes from 50% passing 150 microns to 99.9% passing 30 microns – all in a single pass.