Demand is on the rise for milling systems that can simultaneously produce multiple end products that meet different size specifications from a single feed continuous processing system. The Divorced Classifier from Bradley Pulverizer is often the perfect solution to meet these demands, in fact, there are divorced classifiers currently in operation that are simultaneously producing 4 or more different sized commercial products!

Traditionally, airswept pendulum roller mills are employed to pulverize rigid/friable materials into fine powders from 50% passing 150 microns to 99.9% passing 30 microns whereas vertical shaft impact crushers are employed to crush rigid and friable raw materials to coarse grit specifications. Impact crushers require a capitol cost to purchase and have high energy demands to operate and cannot produce high yields of fine particles. Divorced classification milling systems, on the other hand, can produce high yields of both fine powders and coarse grit in one operation, in one machine, with a much lower demand for energy consumption. In fact, the same amount of power is required to generate fine powders as it is to generate both fine powders and coarse grits. Yes, that’s right, zero additional power is required to generate 2 products simultaneously vs. just one!

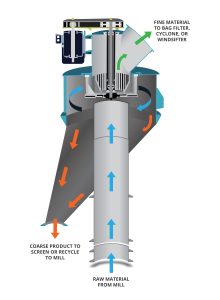

Existing milling systems can be converted to divorced classification milling systems relatively easily as it is differences in the fan and classifier configuration attached to the mill that allows the system to produce multiple products. Divorced classifiers are configured so that fine powders meeting specification travel through the airstream to the cyclone or bag filter for normal particle collection. Additional features are configured in the classification system to allow coarse grit to exit the classifier for screening of grit that meets specification, while out of spec materials are recycled back to the system for further processing. Furthermore, by combining the Bradley Windsifter classifier to the divorced classification system, up to 7 (or more) products of different size can be produced simultaneously.

There are many industries that can and do benefit economically from producing multiple products from a single milling system. For example, coarse grit paint requires particles of fine powder milled in an airswept mill to manufacture the paint itself, but the coarse grit can also be produced in the same system simultaneously for the added grit in the paint. There are limestone mills whose primary duty is to produce fine powders for asphalt filler used during the summer months for road construction. These mills also generate coarse grit for use as animal feed and fertilizer applications, the former being profitable in winter when livestock diets need supplements and the latter being profitable in spring and fall.

Contact us to learn more about how we can convert your milling system from producing a single product to one that produces multiple products simultaneously.