Windsifter Air Classifiers

Stand-alone Air Classifier: Separate Coarse & Fine Particles Simultaneously

Utilizing our proven technology, the Windsifter Air Classifier offers rugged and reliable air classification with efficient and economic operation. This dynamic air classifier provides capacities up to 250 tons per hour, with low power consumption and reduced maintenance.

How It Works

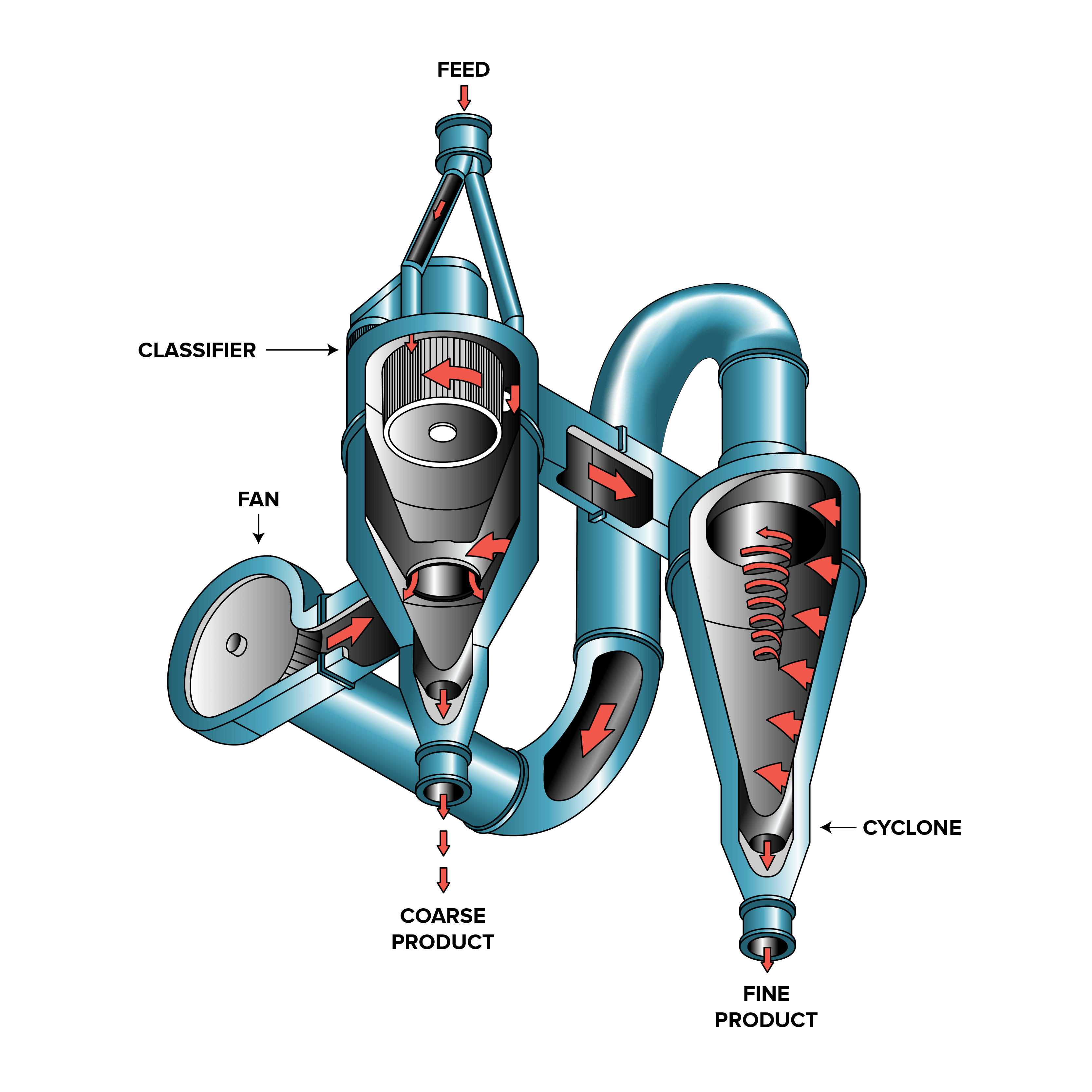

The Vertical Blade Classifier (VBC) technology incorporated into the Bradley Windsifter Air Classifier utilizes vertical oriented blades and the separator rotor to create a vortex, spinning the air and throwing the coarse particles out to the sides, where they fall for bagging. Fine particles are carried through the separator rotor and up to the cyclone or bag filter.

Instant Particle Size Control

The Bradley Windsifter can easily and efficiently achieve separation of desired particle size distribution to meet application demands. The separator rotor speed can be adjusted to produce particle sizes within a range of 5 to 250 microns. The Windsifter can also be used for dedusting of larger stone chip applications. This distinctive design allows instant adjustment of particle size to provide a wide flexibility of operation.

Performance Features

The Bradley Windsifter is available with capacities up to 250 TPH for stand-alone classifying of coarse and fine product simultaneously. With cut points from microns, the Windsifter provides versatility for classifying across many industries and applications. The simple Windsifter rotor has no air purge, so no process bag filter is needed. In addition, this classifier can operate on hazardous materials, with only minimal inert gas consumption.

- No Bag Filter

- Instant Size Control

- Capacities up to 250 TPH

- Sharp Cut

Options include:

- Wear-resistant linings to handle abrasive dust like fly ash and cement.

- Fabricated in stainless steel to classify metal powders and foodstuffs.

- Inert purge for fire and explosion prevention

- Low velocity units for flyash applications

- De-Dusting and Scalping

- Low Maintenance

- Low Power Consumption

Applications

Windsifter Applications:

| MATERIAL | APPLICATION | NORMAL FINENESS | |

|---|---|---|---|

| % passing | microns | ||

| Milled Limestone | Extraction of super-fine powders | 85 | 10-30 top size |

| Narrow size range plastic fillers | 30 top size, min sub 5 | ||

| De-dust dry chippings | 75 | ||

| Agricultural Limestone | Animal feed grades | 90 | 75 |

Testing Services

Bradley Pulverizer is dedicated to helping customers optimize their production and process goals. Laboratory, pilot plant and full scale production tests can be run on specific feeds and based upon given product specifications. Find out more.