For Over 130 Years, Bradley Pulverizer Has Served The Mineral Industries With High-Quality Industrial Airswept Pendulum Roller Mills, Air Classifiers, Separators, and Systems

Grinding, Classifying and Acidulation Processing Solutions

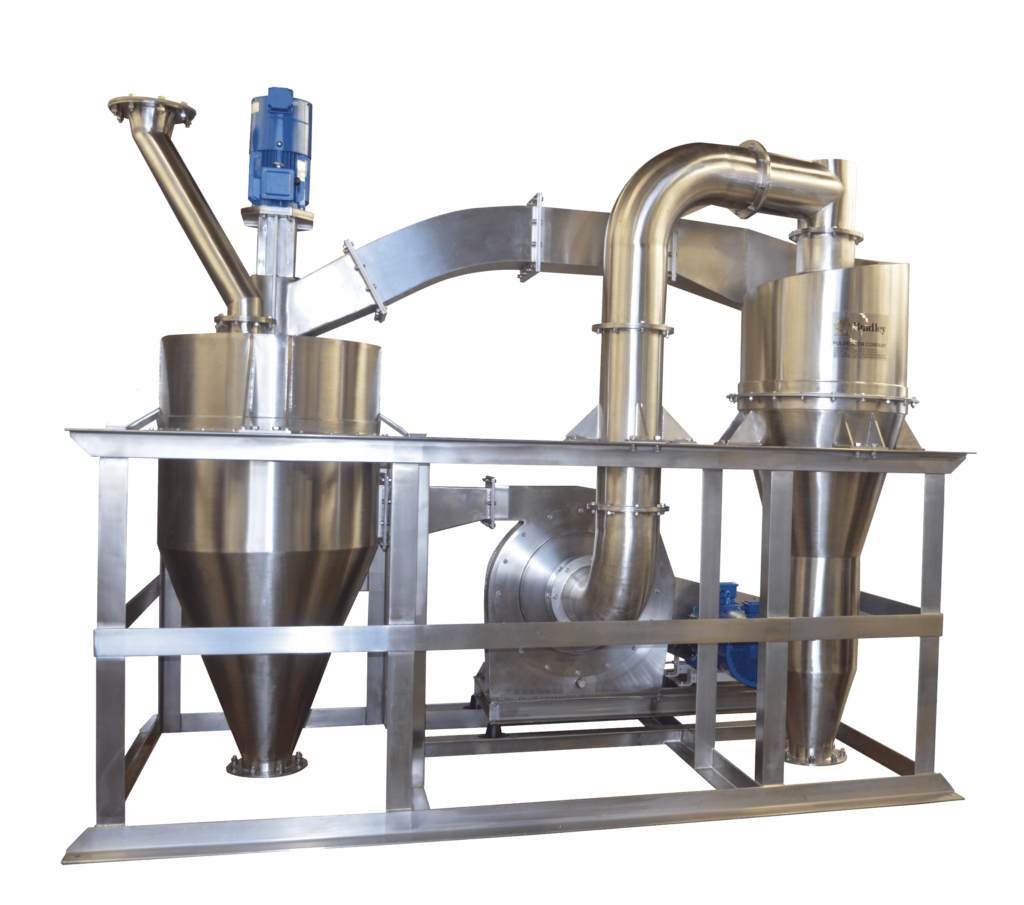

As specialists in the design, manufacture, and deployment of pulverizing systems for fine and semi-fine grinding and classifying, we supply the optimum system from our complete line of pulverizers and classifiers. Our systems are employed in various applications throughout the world and are best suited for use with hard, friable and/or abrasive materials.

Bradley Airswept Pendulum Roller Mills provide a highly efficient and effective system for pulverizing, crushing, and grinding a wide variety of materials.

Bradley Classifiers & Separators offer a range of versatile powder classification solutions. They can be integrated with a Bradley Mill for a complete solution or integrated with other mill systems.

The flexible and reliable design of the Bradley Broadfield Process has been developed from over a century of in-depth process knowledge and experience in SSP manufacturing and other acidulation processes.

Industries & Materials

Worldwide producers of ores, coal, clays, cement, fertilizers, agricultural limestone, slags, pigments, and other minerals all depend on Bradley Pulverizer’s technology, engineering, and equipment to process their materials. Bradley roller mills are widely relied upon for uninterrupted low to high tonnage production of materials which meet the most demanding specifications for particle size distribution.

Latest News

We are proud to announce the relocation of our UK operations to a significantly larger, modernized facility in Sittingbourne, Kent UK, marking a major milestone in the company’s continued investment … Read more

Recent industry events — notably the FICEM Technical Congress in Lima, Peru, and the West Coast Cement Conference — have underscored the cement sector’s accelerating commitment to optimizing grinding processes … Read more

Industries from food processing to battery manufacturing are seeking innovative solutions to improve the efficiency and purity for producing the ultrafine powders that make up the foundation of these industries. … Read more