Semi-fine Grinding & Size Separation for Heavy Duty Applications

Often found in quarries and cement plants, the Bradley Pulverizer Junior Hercules Screen Mill is a proven performer for grinding and sizing materials in one operation. With a compact design and flexible operation, our heavy cast construction screen mills operate reliably for decades.

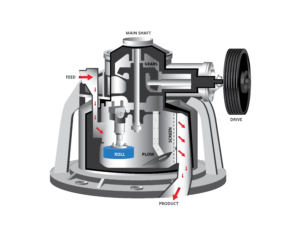

Screen Mill Design

Screen mills are also known as centrifugal ring-roll pulverizers – equipped with two or three pendulum roll assemblies suspended from a rotating carrier. As centrifugal force is created by the rotation of the carrier, the roll assemblies swing outward causing the roller at the bottom of the roll assembly to rotate against the inside of the stationary ring. Material is picked up by and directed between the roller and ring where it is ground using a combination of attrition and impact.

Performance Features

For over 130 years, Bradley Pulverizer has produced reliable, heavy-duty roller mills that are built to last even in the most demanding environments. Bradley Mills are used to process a variety of materials with the most challenging specifications for particle size distribution and feature many functional benefits for our customers:

- Automatic feed control maintains mill at optimum production rate and prevents under or overloading of the mill.

- Improved efficiency due to minimum number of heavy assemblies to yield more TPH

- Low speed means low wear and consistent quality.

- Complete access at ground level allows for easy maintenance.

- Heavy cast construction makes for a robust and reliable operation for decades of performance.

- Vented for dust free operation

- No recycling of oversized particles

- Finished product fineness easily altered

Grind & Screen in One Step

The Bradley Screen Mill pulverizes material between the pendulum rolls and a fixed die ring and can grind feeds as large as 2 ½” to desired fineness in a single operation without auxiliary sizing equipment. Ideal for hard, friable material applications, the mill speed can be altered to match the grinding force required for the material being ground. When the material has been pulverized to the desired fineness, the particles escape from the mill through the surrounding screens and drop through the ports in the mill base to a conveyor installed below the mill.

The fineness of the finished product discharging from the mill is determined by the size of the screen mesh fitted to the mill. The mill screen is designed to provide a large amount of area for easy passage of pulverized material from the mill. The screen itself can be changed easily and quickly to a screen of another mesh size so that various sized products can be produced efficiently in the same mill. Ground materials are then captured below the mill as final product or to be used for further processing. In addition, the mill is vented for dust-free operation.

Specifications

Bradley Screen Mills can achieve:

- Outputs of up to 50 tons per hour

- Product fineness up to 95% passing 2mm with 50% passing 150 microns

| Mill Model | Mill Motor Size | Max Feed Size | Mill Weight | Die Ring Diameter |

|---|---|---|---|---|

| Junior Hercules | 75 kW 100HP |

25mm 1” |

9 tons 19,650LB |

1067mm 42” |

Applications

Ideal for hard, friable material applications, the mill speed can be altered to match the grinding force required for the materials being ground.

| FINENESS PERCENT PASSING | ||||||

|---|---|---|---|---|---|---|

| MATERIAL | CAPACITY (TPH) | 10M | 20M | 60M | 100M | 200M |

| Agricultural Limestone | 8-10 | — | 98-100 | 75-80 | 65-70 | 55-60 |

| Agricultural Limestone | 10-12 | 100 | 90 | 60-65 | 50-55 | 40-45 |

| Phosphate Rock | 7-8 | — | — | 90-95 | 70-80 | 50-55 |

| Clinker | 6-7 | — | — | — | 70-75 | 55-60 |

The output of the Bradley Screen Mill depends upon the grindability of the rock, the amount of moisture present and the fineness of the finished product required.

| Material | Application | Outcomes |

|---|---|---|

| Limestone for direct application to soil | Used to reduce soil acidity | 50% passing 150 micron |

| Agricultural Limestone | Direct soil application to reduce acidity | 50% passing 150 micron |

| Filler for mastic asphalt | Mastic blocks for flexiable sealing joints in roads and bridges | 50% passing 75 micron |

| Unburnt cores from limekiln | 50% passing 150 micron | |

| Gold Ore | Aid in recovery of fine metals and minerals | Fineness varies |

| Diamond Ore | Aid in recovery of fine metals and minerals | Fineness varies |

| Copper Ore | Aid in recovery of fine metals and minerals | Fineness varies |

| Zinc Ore | Aid in recovery of fine metals and minerals | Fineness varies |

| Chrome Ore | For use in metal processing | Fineness varies |

| Manganese Ore | For use in metal processing | Fineness varies |

| Pre-grinding cement raw materials | For feed to ball or rod mill to raise output of existing plants | 50% passing 75 micron |

| Pre-grinding of cement clinker | For feed to ball or rod mill to raise output of existing plants | 40-50% passing 74micron |

| Bentonites | For drilling mud, usually need to dry in Mill | 92% passing 75 micron |

| Marble | For facing ceramic tiles | All passing 2 mm |

| Limestone (pure) | 95% passing 2.4mm |

Contact Us to learn more about how our screen mills may be the perfect fit for your heavy-duty grinding and sizing application