Produce Multiple Products in One Mill System

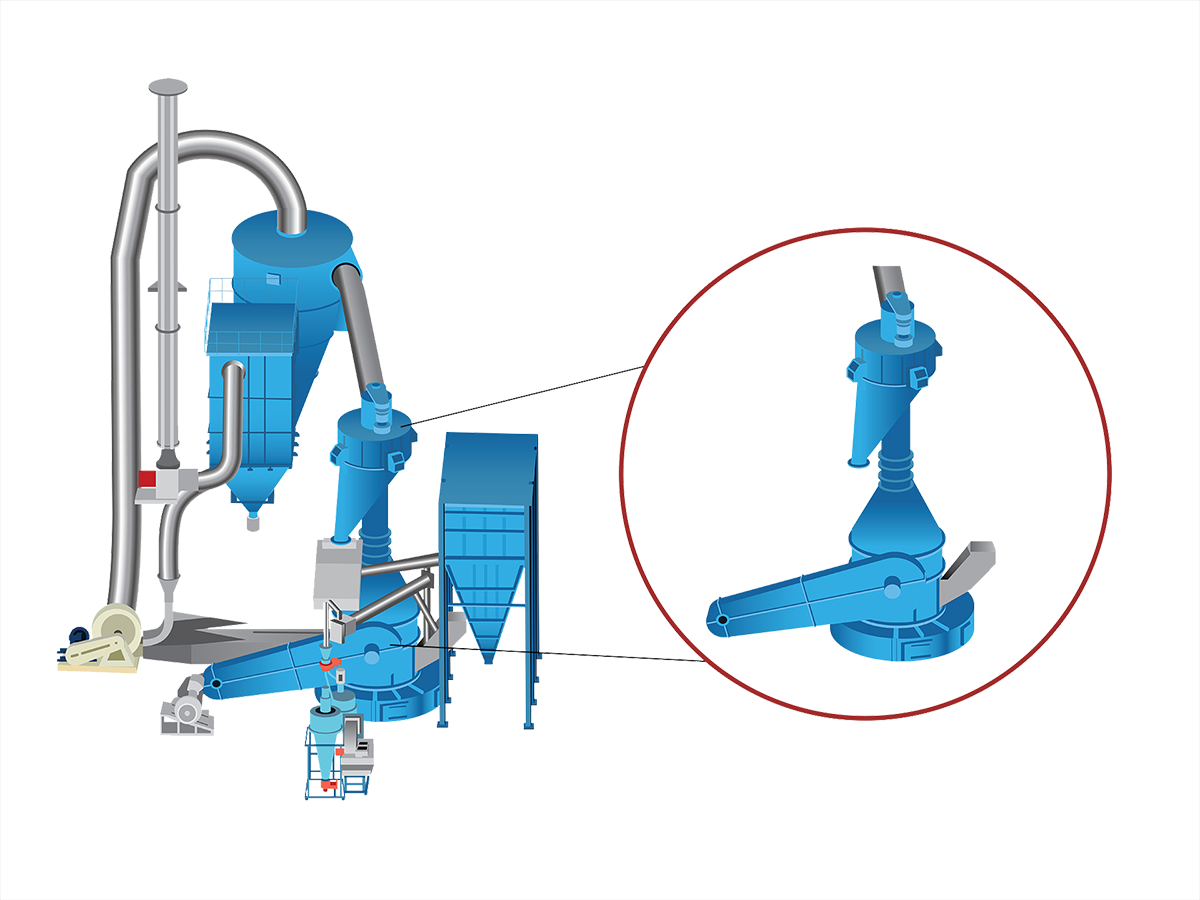

The divorced classifier from Bradley Pulverizer is the ideal solution for producing multiple end products that meet different size specifications from a single feed continuous processing system. The divorced classifier can produce high yields of coarse grit in the same operation where the mill system produces fine powders.

This design also allows for an external recycle of material back to the grinding zone reducing the clouding commonly experienced on mills above the grinding zone and below the classifier, especially when fine grinding. This can result in capacity increases up to 10%.

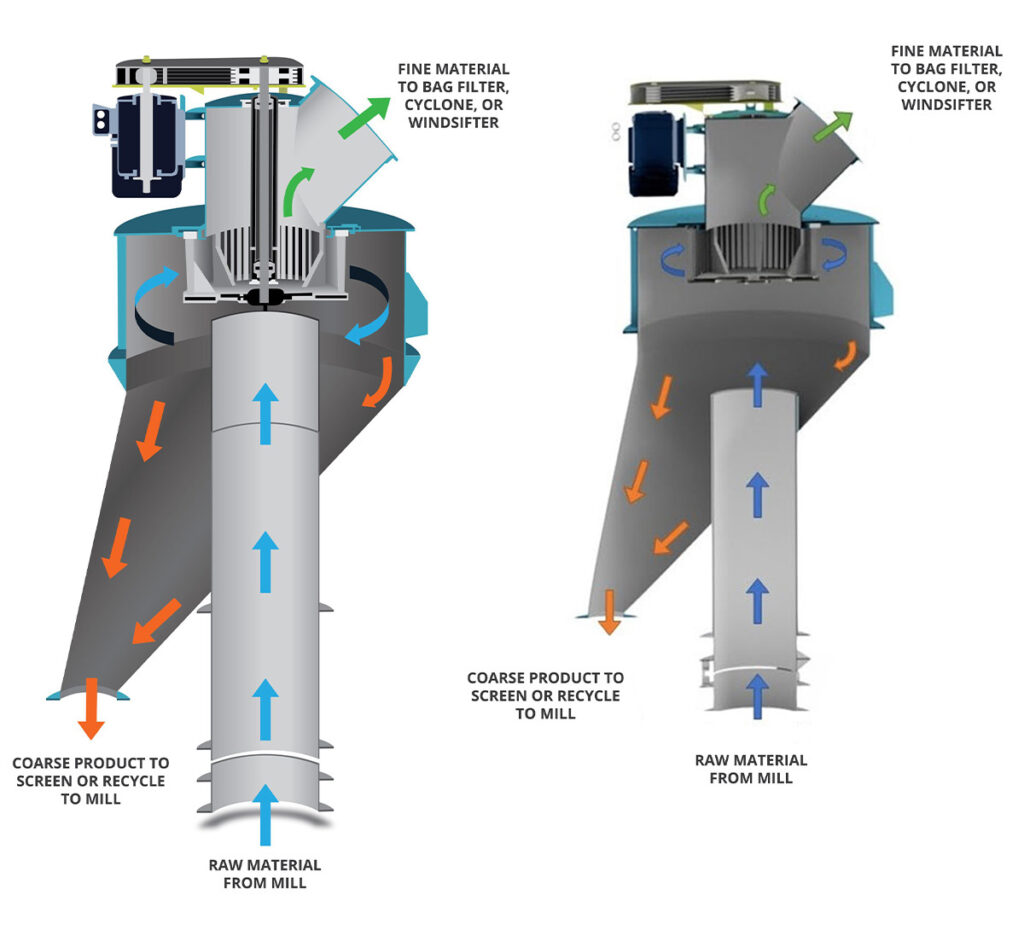

Principle of Operation

Divorced classifiers are designed to connect adjacent to an airswept mill system. The vertical blade classifier allows fine powders meeting specification to continue through the airstream for standard particle collection while allowing coarse grit particles to exit the classifier via the offset cone for secondary screening or return to the mill for further grinding. Out of spec materials are then recycled back through the mill for further processing.

Typically grits can be produced at 1 -1.25 ratio to the fine classified material grades. For example, 10 TPH of 63 micron filler will yield in the region of 12 TPH of grits products.

Performance Features

- Low KW per ton

- Produce numerous end products simultaneously

- Add to any existing airswept mill system

- Low pressure drops

- Reduced material handling & screening

- Simple low maintenance design

- Particle top size cuts of up to 250 microns

- Clean cuts with no air purge or complex labyrinths

- Aize control simply by adjusting rotor speed

Applications

- Airswept ball mills where it’s not possible to put a classifier directly on the mill

- Limestone manufacture of animal feeds and fertilizer where producing fillers

- Recycle of oversized fines out of the main mill airstream increasing capacity

- Combine with an inverted cone to allow top size control on the grit products simultaneously with the fine end control

Contact Us to learn more about reliable air classification with efficient and economic operation.

- Video: Vertical Blade Classifiers

- Video: Airswept Mill Systems

- Article: Options for Improvement in Air Classification

- Case Study: Bradley Mill Overhaul and VBC Upgrade

- Brochure: Divorced Classifiers

- Figure: Classifier Comparison Chart

- Using a Divorced Classifier to Generate Multiple Products Simultaneously from an Airswept Mill System