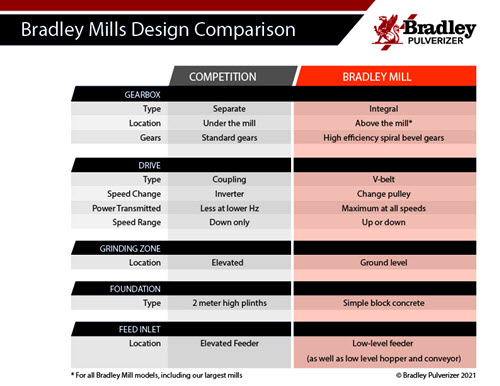

As discussed in our first blog of this series, Bradley Pulverizer is the only manufacturer of airswept roller mills with an overhead integral gearbox on all of our mills (some competitors have an integral gearbox on small mills but not large mills). This design allows for a spectrum of performance and cost saving benefits over other under-driven mills.

As discussed in our first blog of this series, Bradley Pulverizer is the only manufacturer of airswept roller mills with an overhead integral gearbox on all of our mills (some competitors have an integral gearbox on small mills but not large mills). This design allows for a spectrum of performance and cost saving benefits over other under-driven mills.

Performance Benefits:

- Less Vibration: The positioning of the integral gearbox above the grinding chamber adds 30% extra live mass to the mill increasing stability. A reduction in vibration also translates to less gearbox maintenance.

- Improved Efficiency: The spiral-bevel gears used in the Bradley gearbox, similar/identical to the gears used in helicopters, operate with higher efficiency than standard gearboxes used in under-driven mill. This means that almost 10% more of the absorbed power is available for grinding.

- Reduced Gear Wear: Higher efficiency means the Bradley mill gearbox oil does not need to be cooled, even when the mill is used with a dryer. This saves on installation and running costs.

- Optimization of Mill Speed with No Loss of Efficiency: The use of a V-belt drive allows full power of the motor at any speed, which is not possible with a direct drive and inverter which restricts mill capacity.

- Maximize mill Output: The V-belt drive also allows for mill speed to be increased so m output can be amplified without loss of efficiency.

- Safe Maintenance: Wear parts at ground level provide easy access for safe maintenance without the need for access platforms and supporting steel work which can typically use 3 tons of steel.

- Reduced Maintenance Costs: A simple, solid concrete foundation reduces vibration and noise by spreading the mill load over the full area of the block. This reduces the need for gearbox, bearing and structural maintenance.

Installation Benefits:

- Simplified Construction: The over-driven design of the Bradley Mill is installed on a simple, block foundation which uses up to 20% less concrete than plinths needed for under-driven mills. Also, because a Bradley Mill utilizes a ground-level feed intake, the mill feed hopper is at least 2 meters lower than for under-driven mills.

- Reduced Capital & Operating Costs: A simple concrete foundation results in a reduction of installation costs. Bradley mills do not need to be supported on anti-vibration mountings. A lower mill feed intake reduces the costs of support steel work and civil work for foundations for a mill feed hopper. It also reduces the length of the inclined feed belt by up to 7 meters. These features save on operating and power costs.

The Bradley Airswept Mill Value

The Bradley over-driven design of our pendulum roller mills provides for a number of advantages that produce lower operating costs, reduced investment and reduced maintenance. With proper maintenance, Bradley Mills are built to last for decades. Bradley Pulverizer is committed to supporting our customers throughout the lifetime of our equipment and to providing the best value on the market for semi-fine and fine grinding and classifying applications.

Contact Us to learn more about the unique design advantages of Bradley Airswept Roller Mills.

(US) 855-670-8777 | (International) +44 1322-559-106